Documentation: Model 2 Submission

Model

idea

Water Cube/ Beijing

National Aquatics Centre (Facade of the building) by PTW Architects

Technique(s)

to use

CNC milling

Laser

cutting

Vacuum

Former

Processing

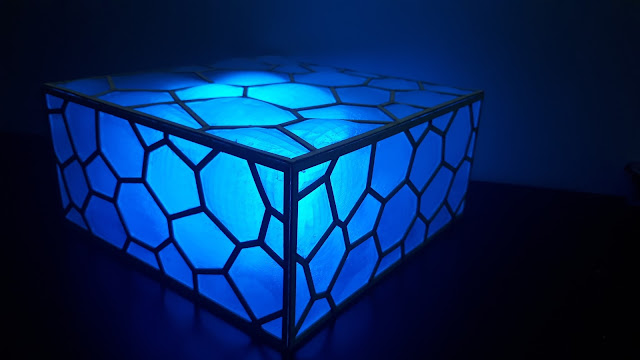

Water Cube

is the precedent of my second model that the façade system is the selected

element for the model. The façade

and structure represent the nature of water which is constructed by the bubble

form structure. The atmosphere of water nature can be enhanced by the building

facade and lighting at night (Figure above).

For the Processing

1.

Design

the 3D model first

For the 3D

model, I use the SketchUp to similar the actual model and the moulds for the

CNC milling.

To making

the shape of bubble on the façade, I do the shape with the Soap Bubble plugin

(perssure is 500)

2.

After that,

I use the CNC milling machine for my two moulds by the pinewood panels (240mm x

240mm). Both moulds are made within three hours.

After that,

I use the CNC milling machine for my two moulds by the pinewood panels (240mm x

240mm). Both moulds are made within three hours.

However,

there is an incident when I do my second mold that the pinewood cannot stick

with the basement well because the double sides task one the wood is not

enough. So I need to restart and redo the system (wrong cutting occurred on the

panel by the figure below).

3.

Making

the façade by the vacuum former

I use the 253mm x 253mm frame as a base to make the shape of model. In this processing, I redo the larger façade twice that the façade I made at first time cannot show the shape clear. It is because I did not press hard during putting down the frame.

I use the 253mm x 253mm frame as a base to make the shape of model. In this processing, I redo the larger façade twice that the façade I made at first time cannot show the shape clear. It is because I did not press hard during putting down the frame.

4. Cutting

the structure (Laser cutting)

By doing

the structure, laser cutting is the method for cutting the structure with the

drawing of Autocad.

The 1mm

screen board is the material for the frame of the model that can highlight the

bubble shape of the façade.

5.

Gluing

all elements together

For the

outcome of finished model, I take some photo by using a lamp as simulation the

night view of Water Cube.

Proposed Size: 8cm (height) x 17.5cm (wide) x 17.5cm (depth)

Material: Polypropylene sheet, screen board, Pinewood panels

Technique: Vacuum Former, laser cutting, CNC milling

Time Commitment:

Design/ drawing time: ~10 hours

CNC milling: ~5.5 hours (3 hours + 2.5 hours )

Vacuum-Forming: 1.5 hours

Laser Cutting: 0.5 hour

Finishing (Cutting + Gluing): 2 hours

Total: ~19.5 hours

Cost/Budget:

Pinewood panels: $17

Screen board: $ 3.5

Polypropylene sheet: $8

Laser cutting booking: $5

Total: $33.5

Comments

Post a Comment